Most products aren’t ready for injection molding right after the first prototype. You often need 20–100 parts to check fit, finish, assembly, and early user feedback—but cutting a steel mold at that stage is expensive and risky. That’s why many teams use a vacuum casting service to produce small batches that closely resemble production parts, without committing to hard tooling.

The “gap” between prototypes and mass production

Most products pass through several stages before reaching the market, but the transition from prototype to mass production is often the most challenging.

Early prototypes are typically built for speed. They prove that a concept works and that a design can exist physically. However, they usually rely on materials and processes that do not reflect real production conditions. The look may be close, but the feel, strength, and consistency are often very different from a finished product. In addition, a handful of prototype units is rarely enough to uncover issues that only appear during assembly or repeated use.

Mass production introduces a different reality. Injection molding tooling represents a long-term commitment. Once a mold is cut, changes become expensive, slow, and sometimes impractical. Any overlooked design issue—no matter how small—can multiply across thousands of parts.

Between these two stages lies a validation gap. Teams need parts that look and behave more like production parts, yet still allow for fast feedback and iteration. A vacuum casting service fits precisely into this gap, offering a way to test decisions before they become permanent.

What is vacuum casting?

At its core, vacuum casting is a process for making small batches of plastic parts that closely replicate production-quality components.

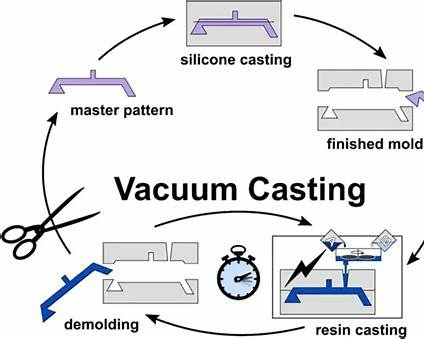

The process starts with a high-quality master model, often produced using custom CNC machining services or high-resolution 3D printing. From this master, a flexible silicone mold is created. Liquid resin—typically a polyurethane resin designed to mimic common plastics—is then poured into the mold under vacuum conditions. The vacuum removes trapped air, allowing the resin to flow evenly and capture fine surface details.

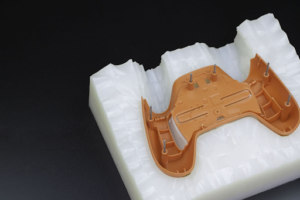

Because silicone molds are relatively quick and inexpensive to make, this process is well-suited for low volumes, usually ranging from a few pieces to several dozen per mold. It is not intended for large-scale manufacturing. Its main value lies in producing parts that feel realistic, look consistent, and behave much closer to injection-molded parts than typical prototypes.

5 reasons teams use vacuum casting before mass production

1) It creates “production-like” parts without committing to hard tooling

One of the biggest risks before mass production is committing to tooling too early. Injection molds are costly, and design changes after tooling begins can be painful.

A vacuum casting service allows teams to produce parts that closely resemble final production pieces—without cutting steel. This is especially useful for housings, covers, structural components, and decorative parts where appearance and fit matter. Teams can evaluate how a product looks and feels in hand before making irreversible decisions.

2) It helps validate fit, assembly, and user experience with real quantities

Single prototypes rarely reveal real-world issues. Problems such as tolerance stack-up, awkward assembly steps, loose fasteners, or uncomfortable button feel often only become visible when multiple parts are assembled together.

By producing small batches, vacuum casting makes it possible to run realistic assembly trials. Teams can test how parts fit together, how they perform during handling, and how users interact with them. These insights are difficult—if not impossible—to gain from one-off prototypes.

3) It’s faster for iteration cycles than waiting for a revised mold

Design changes are almost inevitable before mass production. Adjustments to wall thickness, reinforcement ribs, snap features, openings, or surface details are common as testing progresses.

Revising an injection mold can take weeks or months. Vacuum casting shortens this feedback loop. When changes are needed, a new master and silicone mold can often be prepared far more quickly, allowing teams to move forward without losing momentum.

4) It supports early market feedback and pilot launches

Speed to market matters, especially for startups and competitive consumer products. Vacuum casting enables teams to produce “demo-ready” parts for early users, investors, or distribution partners.

These parts can be used for pilot launches, limited trials, or small-scale sales to gauge market response. Instead of guessing how customers might react, teams can collect real feedback before scaling up. This approach reduces the risk of a poorly received first mass-produced batch.

5) It can be cost-effective for small batches and bridge production

While vacuum casting is not the cheapest option per unit, it can be cost-effective for small volumes. Costs are influenced by factors such as part size, complexity, surface finish, color requirements, and the number of units produced.

Vacuum casting is also commonly used for bridge production—a temporary solution when small quantities are needed while waiting for injection molding tooling to be completed. In these cases, it helps maintain momentum without forcing premature tooling decisions.

When vacuum casting is (and isn’t) the right move

Vacuum casting is a strong option when teams need realistic parts for validation, small pilot runs, or early customer feedback. It works well for appearance-critical components and assemblies where production feel matters more than extreme durability.

However, it is not suitable for every situation. Large production volumes, highly demanding mechanical or thermal requirements, or applications requiring strict material certifications are better served by injection molding or CNC machining. Vacuum casting is a strategic tool, not a universal solution.

A simple checklist before you order a vacuum casting service

1) Define your goal (pick one)

- Appearance check (color, finish, transparency)

- Fit & assembly test (snap fits, screw bosses, alignment)

- User interaction test (buttons, grip, handling)

- Pilot run / small market trial (demo units, early customers)

2) Confirm quantity and volume tiers

- How many units do you need now: 20 / 50 / 100?

- Do you want tiered quotes (e.g., 20 vs 50 vs 100) to compare unit cost?

3) Specify surface and finishing requirements

- Color: natural / dyed / matched to a reference

- Surface: matte / gloss / texture

- Transparency: clear / tinted

- Post-processing: painting, coating, polishing, printing, laser marking

4) Prepare the right files (to avoid back-and-forth)

- 3D files: STEP/IGES (preferred), plus STL if available

- 2D drawing or notes for critical dimensions

- A short note on what must not change (fit surfaces, sealing areas, cosmetic faces)

5) If you plan to go to injection molding later, “design for transfer” now

- Mark expected parting lines (where a split could go)

- Add a draft where possible (even a small draft helps later)

- Call out features that may need revision for molding (thin ribs, deep undercuts)

Conclusion

If you’re not ready to cut an injection mold yet, but 3D-printed prototypes no longer tell you enough, a vacuum casting service is the practical middle step. It gives you a small batch you can assemble, test, and show—then move to mass production with fewer surprises.