In an increasingly competitive manufacturing landscape, the role of the industrial automation component supplier has become central to the success of modern production systems. From sensors, PLCs, motors to advanced control systems, these suppliers allow manufacturers to realize smarter, faster and more resilient operations.

With automation trends evolving based on new technologies and market needs, the need for a dependable component supplier continues to increase. They are the backbone of digital transformation in industry.”

The Core Role of an Industrial Automation Component Supplier

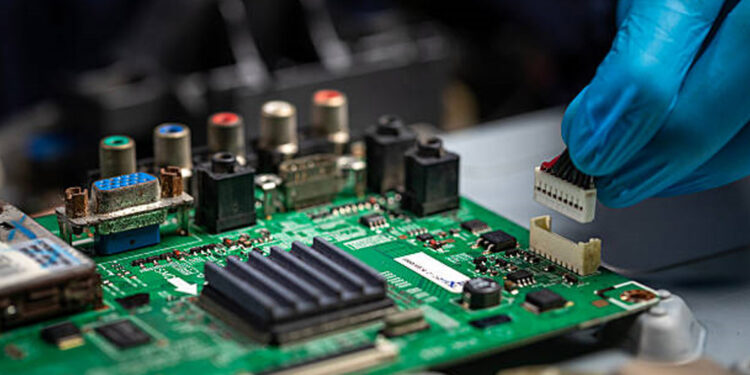

An industrial automation component supplier provides the essential hardware and systems necessary to build, expand, and maintain automated manufacturing environments. These components range from simple discrete sensors and actuators to complex programmable logic controllers (PLCs) and human‑machine interfaces (HMIs). Without a steady flow of these parts, automation systems cannot perform real‑time monitoring, process control, or data‑driven decision‑making that modern factories demand.

Industrial today rely heavily on specialized parts of all kinds — from precision sensors, which measure temperature or position, to edge computing hardware that processes data nearer to where it is collected. This level of complexity makes it so that manufacturers cannot just go to a general electronics provider; they need partners that have the know-how and inventory depth to efficiently support automation deployments.

Driving Industry 4.0 and Smart Manufacturing Trends

One of the biggest drivers for an industrial automation component supplier to play a critical role is that of the accelerated adoption of Industry 4.0 — a concept that has its origins in digital transformation, data integration, and cyber-physical systems. Industry 4.0 strategies are built on technology platforms such as the Industrial Internet of Things (IIoT) and edge computing, which promote real-time monitoring and smart control of the manufacturing process. IoT sensors, automated devices connected to the network, and edge gateways from these component partners were key enablers of this connectivity.

Manufacturers are predicting a growing need for automation in the shape of modular and flexible solutions that facilitate line reconfiguration and quick response to market changes. Vendors who offer flexible, interoperable components allow businesses to move away from rigid assembly lines towards logical, data-driven systems of production. This versatility enables a tremendous amount of product customization and keeps line-change downtime to a minimum — a huge competitive advantage in today’s market.

Automation trends, such as rising sales of collaborative robots (cobots) — robots that share the space with human operators — , also have a significant share of specialized components, such as force sensors, safety drives and user-friendly control systems. Vendors who excel in these areas enable manufacturers to embrace automation that delivers even greater safety and productivity improvements.”

Enabling Predictive Maintenance and Operational Efficiency

One critical advantage that an industrial automation hardware supplier provides is support of predictive maintenance. Conventional maintenance methods respond to failures after they happen, with costly downtime. Instead, real-time data on the performance of equipment is collected by smart sensors and condition monitoring modules from automation manufacturers. This information enables systems to predict failures before they occur and perform maintenance in a more proactive manner — leading to increased uptime and extended equipment life.

In addition, automation products which facilitate higher levels of diagnostic and analytic capabilities enable manufacturing teams to fine tune processes, minimize waste and improve quality assurance. Data from edge-connected devices is collected and fed into larger analytics platforms for continuous improvement across the manufacturing organization.

Building Resilience and Supply Chain Efficiency

With rising emphasis on supply chain resilience, manufacturers are looking for automation partners who can ensure reliable delivery and inventory support. An industrial automation component supplier often plays a strategic role in securing critical parts, mitigating supply risks, and shortening lead times. By maintaining robust stock levels and diverse sourcing strategies, these suppliers help companies avoid production delays that could arise from global disruptions.

And since modern supply chains are now more and more incorporating automation solutions into warehousing, logistics, internal transport, etc., the parts that these suppliers produce enable for smooth end‑to‑end operation. Automated sortation systems, autonomous mobile robots and intelligent material handling systems are just a few examples where components must be delivered on time and work reliably to maximize throughput.

Supporting Global and Local Manufacturing Needs

#Humanized response

The industrial automation market is on a global level, however regional supply chains have an influence. An industrial automation part supplier that serves globally — like distributors that are situated in industrial clusters or multi-regional networks — is able to provide competitive pricing, effective logistics, and assistance for multinational companies. These vendors assist manufacturers address complicated markets and meet regional requirements reinforcing standardization of automation deployments across sites.

Meanwhile, local suppliers are essential for agility and quick turnaround, particularly for emergency repairs or custom automation requirements. Industrial automation suppliers combine global knowledge and local support to maximise system up time and minimise operation risk.

Contributing to Sustainability and Energy Efficiency

Sustainability has become a major priority for manufacturers, and automation components are pivotal in achieving energy‑efficient operations. Suppliers who innovate in low‑power drives, energy‑saving motor controls, and smart power management components enable factories to reduce carbon footprints and align with environmental goals. This focus on sustainability not only lowers operating costs but also supports compliance with evolving regulatory requirements worldwide.

Conclusion

In a nutshell, the industrial automation parts provider is a part of the modern manufacturing evolution — not just a source of parts. These vendors are helping companies address the challenges of Industry 4.0 and beyond by enabling smart factory technologies, facilitating predictive maintenance, enhancing supply chain resilience, and driving efficiency and sustainability. With the changing face of automation, suppliers to these markets continue to be key players in operational excellence, competitive advantage and long‑term industrial growth.