Overweight violations rarely happen because of one dramatic mistake. More often, they creep in through routine decisions: an extra pallet added at the last minute, a misdeclared weight from the supplier, or an optimistic assumption about how much a container can “still take.” Anyone who has ever watched a team repack a trailer in the yard on a Friday afternoon knows how painfully real that scenario is.

Yet the consequences are everything but routine. Beyond fines, overweight violations disrupt schedules, trigger cargo damage risks, jeopardize insurance coverage, and strain customer relationships. And because a large share of citations stem from axle imbalances rather than total weight, the problem is more nuanced than simply staying under the gross limit.

This article walks through a realistic, operations-focused approach to avoiding overweight violation risks, using predictable steps, smarter tools, and a few field-tested habits that experienced shippers rely on every day.

Why Overweight Violations Happen More Often Than They Should

Shippers tend to think in totals—total cargo weight, total container capacity, and total allowable limit. Regulators, however, think in distribution. In the US, the 80,000-lb gross vehicle limit is only part of the picture; the 20,000-lb single axle and 34,000-lb tandem axle limits create a chess game where each pallet affects the entire configuration.

Real-world moments where violations happen:

- A warehouse loads heavy cartons close to the doors “for easier unloading,” shifting mass toward the rear axle.

- A shipper works with approximate product weights provided by upstream suppliers. A 3–5% inaccuracy doesn’t sound like much until you scale it across 900 units.

- A team assumes a 40′ container offers “more weight tolerance,” not realizing that container weight limits are often dictated by the weakest leg of the journey (local roads, port equipment, or cross-border rules).

The result? A shipment can be compliant on paper yet non-compliant at the first weigh station because its center of gravity is off by less than a meter.

A simple rule of thumb: If the load looks visually uneven, the axles usually reflect it.

Practical Methods to Prevent Overweight Violations

Shippers with low violation rates share a few consistent habits. None are complicated, but together they prevent the cascading issues that lead to cargo damage, rejected loads, or schedule chaos.

1. Start With Verified Weights, Not Assumptions

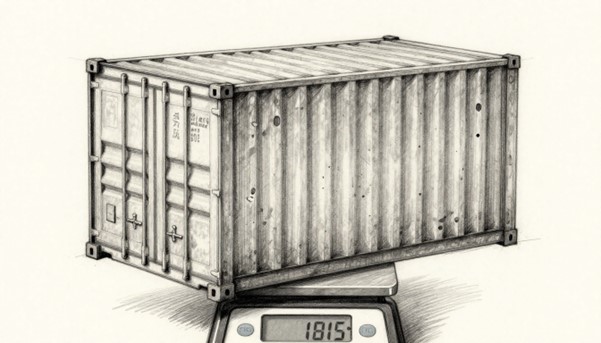

The tare weight of containers is fixed—2,280 kg for a standard 20′ and around 3,700 kg for a 40′—but product weights rarely are. If your suppliers give only rounded numbers, run a small sample audit. A quick sampling exercise often pays for itself within a week.

2. Model Weight Distribution Before Loading

Teams often rely on “visual sense,” but axle limits don’t reward intuition. A better method is to sketch the container’s floor plan and mark heavier SKUs in advance. Even a simple whiteboard mock-up reduces mistakes.

For B2B shipments involving mixed cartons, a more robust approach is using a load calculator, especially one that visualizes placement and flags axle imbalances. One option you can try online for free is available here.

A quick simulation can save hours of reloading and prevent a violation before the truck even leaves the yard.

3. Prioritize Stability and Cargo Damage Prevention

Weight compliance isn’t just a regulatory checkbox. Misplaced heavy items create dynamic forces during acceleration, braking, or port handling. One freight forwarder describes it this way: “A pallet that’s 300 kg out of place becomes the equivalent of pushing a refrigerator through your cargo when the truck brakes hard.”

To reduce cargo damage incidents:

- Place the heaviest items low and centered.

- Avoid stacking heavy-over-light when goods are fragile or high-value.

- Use blocking, bracing, and friction mats for shipments susceptible to shifting.

Stability and compliance go hand in hand; protect one, and you improve the other.

4. Document Everything Early

Carriers, freight auditors, and insurers increasingly expect transparent documentation: verified gross mass records, photographs of loaded pallets, material lists, and scale tickets. When inspections happen, paperwork often determines whether cargo continues its journey or gets held for clarification.

Think of documentation like a digital trail proving diligence, not paperwork for paperwork’s sake.

What to take away: prevention is mostly process. Small habits create predictable compliance.

How to prevent overweight violations – Checklist

The Role of Technology: From Guesswork to Predictable Compliance

A growing number of B2B shippers rely on digital tools to eliminate human error in loading. The difference compared to traditional spreadsheets is dramatic.

Modern solutions can:

- Visualize loads in 3D, including center of gravity and axle impact.

- Optimize placement to reduce empty space while staying under all container weight limits.

- Help prevent cargo damage by suggesting safer placement for fragile items.

- Export loading plans for warehouse staff, reducing miscommunication.

For companies handling varied SKUs or shipping weekly from multiple facilities, automated planning often recovers dozens of labor hours per month and reduces claims from cargo damage by a measurable margin.

What to take away: software doesn’t replace expertise, but magnifies it by removing preventable mistakes.

Conclusion: Build a Weight-Safe Culture Before Problems Arise

Avoiding overweight violations is about designing a workflow where errors have fewer chances to appear. Verified weights, planned distribution, simple documentation, and the use of a reliable load calculator all contribute to a system where compliance becomes the default outcome.

Companies that treat weight planning as part of supply chain risk management not only avoid fines, but they also ship more predictably, experience fewer damaged-goods claims, and maintain stronger carrier relationships. In an industry where margins tighten every year, eliminating these preventable disruptions is a competitive advantage in itself.